第八届全国微全分析系统学术会议微全分析专场

2013年5月16日-19日,由中国化学会主办、厦门大学承办、复旦大学、浙江大学协办的为期四天的第八届全国微全分析系统学术会议、第三届全国微纳尺度生物分离分析学术会议暨第五届国际微化学与微系统学术会议在美丽的海滨城市厦门隆重召开。以下是微全分析专场报告。

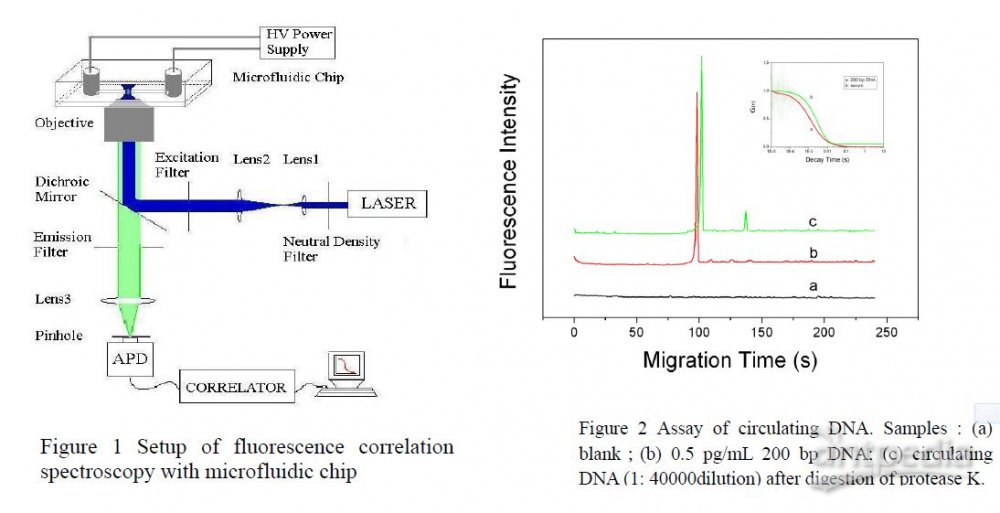

来自上海交通大学的任吉存教授为我们带来了题为《Microfluidic Chip with Fluorescence Correlation Spectroscopy》的精彩报告,以下是内容摘要:

In this work, we presented an analytical system for coupling fluorescence correlation spectroscopy (FCS) with microfluidic chip (as shown in Figure 1). FCS is a sensitive single molecule technique based on measuring the fluorescence fluctuations in a small volume. When a molecule diffuses into and out of the tiny illuminated volume, or when a chemical reaction occurs in this volume, a fluorescence fluctuation can be tracked. The highly-focused detection volume was obtained with a high numeric aperture (NA) water immersion objective. The photon signals were collected by a single photon counting module. Utilizing the water immersion objective with 60×1.2 (NA) and the 35 μm pinhole, the highly-focused Gaussian volume was obtained of about 0.3 fL. Meanwhile, we developed a simple method for fabrication of poly(dimethylsiloxane) (PDMS)/glass microfluidic chip[2]. An irreversible sealing was formed between the PDMS replica and glass by UV irradiation. This microfluidic chip with FCS was used to capillary zone electrophoresis and isotachophoresis. This method was used to measure the surface charge of quantum dots and determine the circulating DNA in sera samples (as shown in Figure 2).

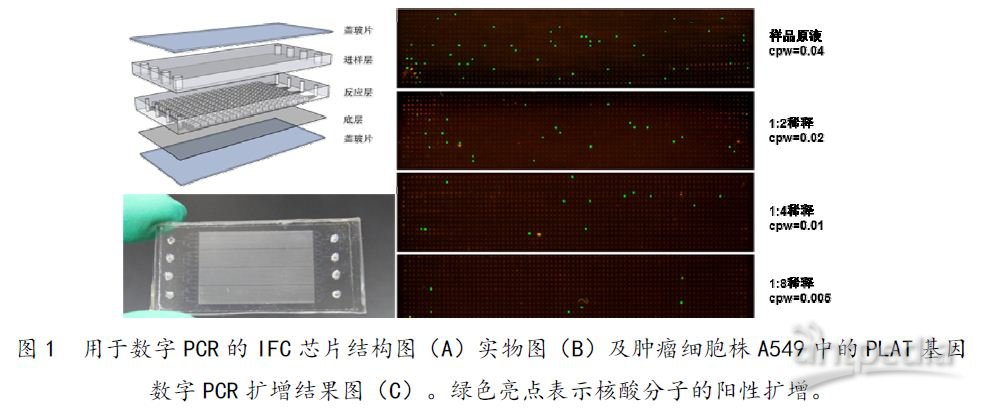

来自浙江大学的牟颖教授为我们带来了题为《自吸离散化数字PCR 芯片的研究》的精彩报告,以下是内容摘要:

数字PCR 技术能进行单分子扩增,实现核酸初始拷贝数绝对定量,因此被认为是极为准确灵敏的检测技术[1],在生命科学领域意义重大。目前报道的主要数字PCR 装置有:离心转盘芯片[2]、滑动芯片[3]、液滴芯片[4,5]以及集成流路(IFC)芯片[6]。然而上述装置需要繁杂的外部设备,如注射泵、气压源等控制系统来实现样品的注入以及分配操作,进样耗时长,操作繁琐,易造成样品的丢失,降低检测的灵敏性及准确性。本文研制了一种样品自吸式无泵无阀数字PCR 芯片,该装置应用PDMS 本身所具有的容气性质,靠储存的负压引入样品,通过油相封隔的方法自动实现样品在各个小室的分配,实现了数字PCR 进样和隔离的自动化,通过PCR 方法实现核酸的单分子扩增检测,如图所示。基于自吸式离散化芯片的数字PCR 不仅具有和目前几类商品化的数字PCR 平台同样的准确性(绝对定量)和敏感度(单分子),而且更为简便、省时,容易推广应用。

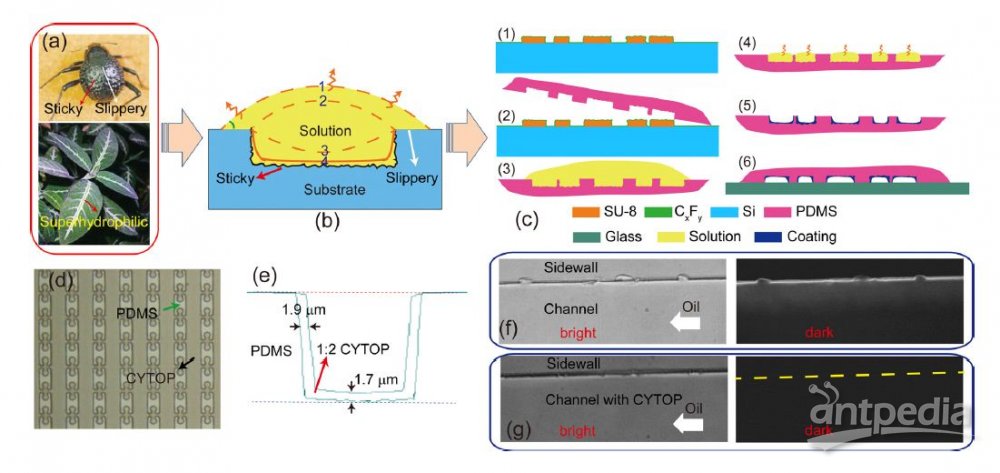

来自中山大学的吴天准教授为我们带来了题为《基于润湿特性仿生的PDMS 功能涂层自图形化》的报告,以下是内容摘要:

PDMS 微流控芯片常需要各种表面改性,而已有的各种气相、液相涂层方法都难以保证涂层覆盖准确性和均匀性。受非洲沙漠甲虫及超亲水叶子的润湿特性启发,我们提出一种极为高效、便捷的PDMS 表面涂层自图形化 (self-patterning) 方法。动植物的亲水、疏水润湿特性可高效地操控液体的黏、滑行为(图a),因此,我们通过粗糙度设计润湿梯度,以蒸发为驱动力便可精确地将溶质沉积、固化在粗糙的3D 微通道上,而不会留在光滑顶面(图b)。利用氧气等离子体选择性攻击SU-8 而非Si 的特点,可便捷地把SU-8 与Si 的粗糙度复制到PDMS 上,从而使涂层蒸发后只分布在通道内,兼容PDMS-玻璃邦定(图c)。利用此方法,我们示范了疏水CYTOP 涂层在PDMS 复杂流路中的100%覆盖准确性和良好的均匀性(图d-e)。与无涂层PDMS 相比,溶胀被显著抑制,非特异性荧光染料吸附被有效消除(图f-g)。这种自图形化方法廉价、高效、快速,可广泛用于PDMS 微流控芯片使用各种功能涂层进行表面改性。

来自大连化物所的刘显明教授为我们带来了题为《Measurement and Intelligent Control of Electrowetting-actuated Droplets by Means of Electronic Approaches》的精彩报告,以下是内容摘要:

In digital microfluidics (DMF), transportation of droplets was determined by the on-off output (0 or 1) of its control system, which applies a voltage on the actuation electrodes underneath and thereby generates unidirectional electrowetting forces on droplets. Such an actuation mechanism provides a technical shortcut to the programmability of automation functions and even more advanced intelligent control, the latter of which autonomously coordinates objects in accordance to human intelligence and experiences.

Here we present a way of establishing an intelligent control-engaged actuation and routing system for droplets on DMF chips. First, we looked into the intricacy of a digital droplet in their hydrodynamics by real-time impedance measurement [1] and image capture; second, based on the data obtained from hydrodynamic studies, we used a fuzzy control module to coordinate the charging timing of working electrodes and an overall 20% shorter actuating time was obtained, compared with that engaged in a proportional-integral-derivative controller (PID controller) [2]; third, we established a routing coordinator for multiple digital droplets while providing a possibility for an autonomous and preliminary “fire-and-forget” management function.

来自南京大学的吴增强教授为我们带来了题为《β-Galactosidase / Glucose Oxidase Cascade Reaction in Microfluidic system: Convection and Diffusion Interaction》的报告,以下是内容摘要:

In the processes of metabolism, the high energy conversion and great turnover number are exemplified by sequential enzymes catalytic reactions. These phenomena indicate multi-enzymes cascade reactions have more advantages than single enzyme in the bio-fuel cell, detections fields and modeling reaction pathways within cells1-3, However, the challenge is critical to reveal how biology integrates temporal and spatial information to determine the biological function. What is more, understanding the effect of spatial organization on enzymatic activity in multienzyme systems is not only fundamentally interesting, but also important for translating biochemical pathways to noncellular environments. Here, based on the our pervious research by using Scanning Electrochemical Microscopy (SECM)4, a study of distance-dependence for the activity of β-Galactosidase (β-Gal)/ Glucose Oxidase (GOD) cascade by immobilizing β-Gal/GOD on Polycarbonate (PC)/PDMS hybrid microchip is reported in this paper. A schematic representation of enzymes cascade reaction in microchannel is outlined in Figure 1. The influence of spatial distance and velocity on the kinetic of enzymes cascade reaction was investigated by using electrochemical detection at the end of microchip. A 2D finite element model was applied to understand the effect of mass transport on the spacing-dependent enzymes cascade reaction kinetics.

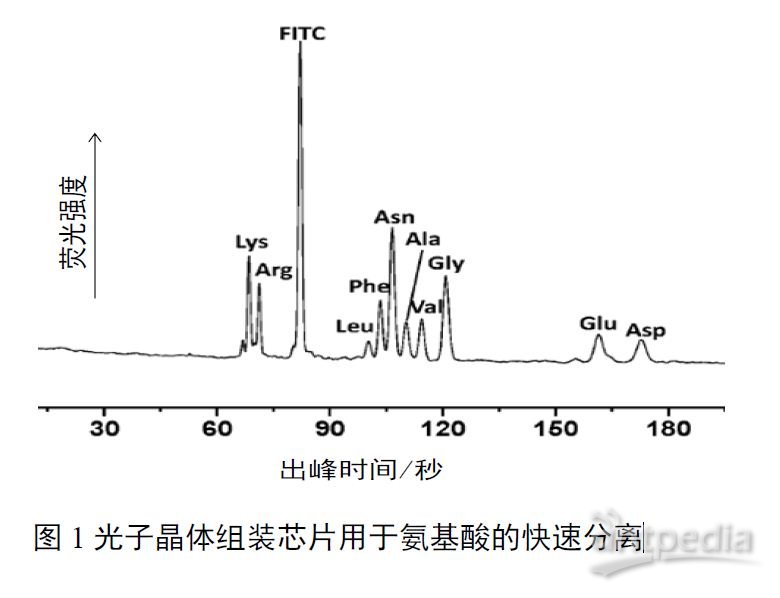

来自中国科学院化学研究所的陈义为我们带来了题为《光子晶体微流控芯片的制备与应用》的报告,以下是内容摘要:

微纳流控方法有显著的理论优势,其基础研究也因此迅速发展直至今日,唯实用化研究颇有难度。原因甚多,其中流体调控困难和通道表面非特异吸附放大效应,十分关键。现有芯片分离速度虽快,但峰容量过小,因而无力分辨复杂样品中的诸多成分,这是一个更现实的问题,至今难解。我们对此进行了一些探索,考虑了引入稳流和峰扩容机制,提出了构造规则或周期性的微纳复合通道结构的策略,尝试了将光子晶体[1]Photonic crystals,记为PCs)融入微流控概念的做法,设计制备出了PC 型微纳流控芯片,研究了其高速分离问题并取得了进展。PCs 是一类周期性电介质物质,既有天然产物,亦可人工合成,在光学通讯、光子线路设计、光学器件研制等领域中的发展非常迅速,但在分离分析领域中的研究进展缓慢。我们认为,利用PCs 中巨大的比表面积和3D 纳米孔网结构,可以诱导高稳流动,获得高速和高效分离,因为纳米通孔不仅具有尺寸筛分作用,还能缩短传质距离,强化物质的分配作用。实测表明,PC 型微纳流控芯片的分离塔板高度可小于300nm,优于普通毛细管电泳;此类芯片不仅可以实现高效、高速、高重现性的分离[2],而且可以有效提高峰容量,能用于混合氨基酸(图1)、肽或蛋白水解产物等复杂样品的分离分析;结合使用手性选择剂,还可实现手性物质的高速拆分。种种迹象显示,PC 型微纳流控芯片深具发展潜力,值得大力研究。不过,目前还没有商品可用,须自己制备。我们已为此建立了快速制备PCs 的方法[2],可用于不同形状和结构芯片中高稳定性PCs 的构建,欢迎查考引用。

来自南京大学徐静娟教授为我们带来了题为《微流控芯片上的电致化学发光分析》的报告,以下是内容摘要:

微流控芯片的信号检测装置是微流控分析检测系统的重要组成部分。检测器的性能对整个分析系统的灵敏度、线性范围、检测速度有很大的影响。电致化学发光(ECL)法结合了电化学与化学发光的优势,因此,它有着很高的灵敏度与选择性。随着双极电极的出现,微流控芯片在ECL 方面的研究也越来越多。它与传统的三电极系统有着明显的不同:双极电极上的电位由溶液中的电场决定的,而且不需要用引线将电极引出,这大大的简化了芯片制作的复杂程度。到目前为止这种方法还很少被应用于分析检测领域。我们实验室用光刻法和化学刻蚀法制备了光透的ITO 双极电极,由于ITO 电极的透光性使得它非常适合于高灵敏的ECL 检测。利用叶酸与肿瘤细胞表面高表达的叶酸受体之间的高亲和能力以及叶酸对钌联吡啶的高效猝灭效果实现对肿瘤细胞的检测,并观察到了叶酸在细胞内的胞吞胞吐现象。除了检测细胞表面物质,这种无线电致化学发光法还首次用于细胞内的c-Myc mRNA 的检测。由于mRNA 容易水解,因此,我们用耐水解的DNA 取代mRNA。首先将双链DNA 用量子点标记,再转移到细胞内。通过DNA 与mRNA 的杂交,使得蛋白质的翻译受阻,引起肿瘤细胞的凋亡。同时使得单链DNA 从量子点上释放,并被电极表面的钌联吡啶纳米粒子标记的DNA 所捕获。无线电致化学发光技术除了用于高灵敏的化学传感还可以用于生物成像分析。通常生物成像技术受背景信号的干扰较大,我们设计了一种双管道的微芯片-ECL 传感器,利用电子开关来降低背景信号,提高成像的灵敏度,成功检测了前列腺抗原(PSA)。

来自厦门大学的周勇亮教授为我们带来了题为《Low-cost fabrication of glass based microfluidic chips by PAG electrochemical soft stamping》的精彩报告。以下是内容摘要:

Glass chip is an important and commonly used materials for microchips due to its excellent properties. Conventional method for the galss chips is based on UV lithography, which requires specialliazed equipments and represnents a barrier to the mass production of glass microchips[1]. Campbell et al. proposed the direct printing microstructures onto glass by agarose stamps soaked in HF etching soluton[2]. Hanners developed a method that combines PDMS microcontact printing and wet etching[3]. However, compared with chemical etching, electrochemical etching has higher accuracy and controllability. Our group has developed electrochemical wet stamping technique, to electrochemical etch silicon or metal surface using agarose gel soft stamps[4]. Here, we reported that by using polycarylamide hydrogel (PAG) as electrochemical soft stamps, galss chips could be fabricated in mass with cost as almost one fifth of that of UV lithography.

The apparatus and process of electrochemical soft stamping was shown in figure 1. Electric field was applied between PAG soft stamp and the metal film waiting for fabricated. PAG soft stamp was cast on silicon/photoresist mold which was fabricated by nanoimprint, the dimension of smallest structure is around 300 nm.

As shown in the figure 2, the Young’s modulus of PAG stamps were obtained by fitting the approaching curve with Hertz model based on the AFM force-distance curves of the PAG stamps. The effect of the Acr and bis concentration to stamp modulus were discussed as a basis to explore the stamp stress and strain under pressure by using ANSYS simulation, the results show that the Young’s modulus of PAG gel is 4.46 MPa, which is around 2 orders of magnitude higher than that of agarose gel.

After optimized the processes and parameters, such as etching potential, pressure, time, pattern shape and the wetability of the surface of the fabricating metal, microgroove structures with high quality have been fabricated (Fig 3). And the fabbrication cost of glass chips is about 33.4 RMB per chip ( yield > 50), while that of UV lithography is 148RMB (Fig 4).

来自湖南农业大学的周铁安教授为我们带来了题为《Novel Voltage Controlled Solid State Pumps Using Microchannel Plates》的报告。以下是内容摘要:

Microchannel plates (MCP), 2.1 cm in diameter, 0.40 mm thick, and with 3 million uniform holes 7 microns in diameter, have been used for pumping ethanol, 2-propanol, methanol, acetone and water. Pumping started at dc voltages as low as 6 V, and a pumping rate of 15-18 ml/min was achieved at 200-250 V for ethanol. The pumping rate was found to be directly proportional to the voltage drop, DV, applied across the channel plate at voltages ≥ 100 V, in agreement with the conventional electro-osmotic equation. Highly reproducible results were given by several MCPs continuously working in ethanol for over one week. Enhancing pumping was realized by stacking of several MCPs in various configurations. In addition to the surface charge induced by surface dissociation and specific adsorption, an additional space charge governed by the field effect in the n-type MCP semiconductor device was found to play an important role in the electro-osmotic pumping. This new mechanism also explains well for the intriguing phenomena described in a recent publication[1] that MCP shows a unique characteristic of directional preference in pumping with net flow consistently induced toward the nearest electrode regardless of polarity of the voltage potential applied. Other electrohydrodynamic (EHD) mechanisms involved in preconditioning of the plates are also discussed. The devices have potential application in voltage controlled micropumps.

来自中科院上海微系统与信息技术研究所的李刚教授为我们带来了题为《A self-contained metering and mixing microfluidic device for lab on a chip》的精彩报告,以下是报告摘要:

Over the past decade, there has been an increased interest in the development of miniaturized analysis devices. One of the most expected features in these miniaturized devices is the integration and automation of liquid operations for biochemical analysis applications [1]. In spite of intensive effort on microfluidics, there has been no practical solution for the integrated and easy-to-use liquid handling technique. Thus, a power-free device is proposed in the present study for nanoliter fluidic handling on a chip.

Fig. 1 shows the schematic of the microfluidic device based on the pump/microchip assembly. It is assembled by reversibly bonding a PDMS slab containing a group of microchambers on a PDMS chip containing a microchannel network. The PDMS chip contains 24 parallel microstructure units. All units are connected by a common feeding channel and each unit comprises a centre metering structure, a peripheral metering structure, a reaction chamber, a peripheral inlet port, and an air venting port. In the combination, the PDMS slab acts as a pump to provide pumping power, which is pre-degassed and then attached to the outlet ports of the microchip to create a negative pressure for driving fluid by absorbing the air in the channels [2]. In addition, a sudden contract of cross-section is designed at the end of each metering channel, which acts as a geometrical stop-valve. During operation, a pre-degassed modular PDMS pump was firstly placed onto the outlet ports of the microfluidic chip, and then aliquots of liquid samples were dispensed into the inlet reservoirs. Due to negative pressure generated inside microchannels by the air dissolution into the pre-evacuated PDMS pump, the samples were automatically sucked into the feeding channels. When the advancing liquid fronts reached the joints between the metering channel and the connection channel, they stopped owing to capillary pressure barriers. Subsequently, air was introduced into the feeding channel to remove the excess liquid, and droplets of precise volumes were left in the metering channels. With a further absorption of the air in the closed channel-reservoir system, the negative pressure increased and pushed the metered droplets into the connection channel, and finally transported the mixed droplet into the reaction chamber. Fig. 2 shows snapshots of the metering and mixing of two food dye solutions in the proposed microfluidic device.

-

企业风采

-

企业风采