诚信认证:

工商注册信息已核实! 扫一扫即可访问手机版展台

扫一扫即可访问手机版展台

Micro Material 纳米力学测试系统—纳米压痕

Thin films and coatings (from a few nm to about 1 µm thick) need to be optimised both in the mechanical properties and tribological performance.Typically, this is done with a combination of indentation and scratch tests.Conventional scratch test conditions are not appropriate for these types ofmaterials as they were developed for testing thicker coatings. Instead thenano-scratch & wear module can provide what is needed. Figure 1: Ramped scratches to 500 mN show brittle fracture of 1.5 µm TiFeN films on Si at high load.

properties and tribological performance.Typically, this is done with a combination of indentation and scratch tests.Conventional scratch test conditions are not appropriate for these types ofmaterials as they were developed for testing thicker coatings. Instead thenano-scratch & wear module can provide what is needed. Figure 1: Ramped scratches to 500 mN show brittle fracture of 1.5 µm TiFeN films on Si at high load.

How it works

The sample to be tested is moved perpendicular to the scratch probe whilstthe contact is either held constant or ramped at a user-defined rate.Throughout the test the probe penetration depth and tangential (frictional)load are continuously monitored. Single and multi-pass tests are possible. Multi-pass tests allow the investigation of nano-wear and micro-wear.

The Nano-Scratch & Wear module has found many applications in sectorsas diverse as optical, microelectronics, polymer/biomaterial, and tribologicalcoatings. It is available as a stand alone instrument (nano-scratchtester) or as an option for the NanoTest Vantage platform.

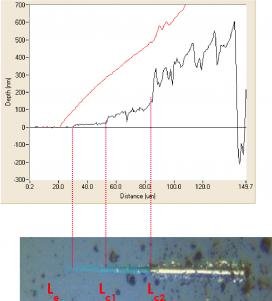

Ramped scratch, corrected for baseline sampletopograp

Figure 2 shows a scratch test with 3 µm end radius probe scanning over a 150 µm track at a scan speed of 2 µm/s.

Figure 2 shows a scratch test with 3 µm end radius probe scanning over a 150 µm track at a scan speed of 2 µm/s.

A pre-scratch scan was carried out using an ultra low contact force inorder to assess baseline sample topography.

The red line shows the on-load probe depth, which represents elastic and plastic depth. After 20 µm the load is ramped at 2.5 mN/s.

The black line shows the residual (plastic) depth once the scratch loadhas been removed. This has been corrected for initial sample topography.

The frictional force on the indenter can be recorded throughout theexperiment.

Micro-scratch Testing

The 30 N high load head can be used across the full load range formicro-scratch and micro-wear testing. The frictional force on the indenter canalso be recorded throughout the entire load range.

This high load scratch capability is available on NanoTest Vantage and NanoTest Xtreme instrumentsequipped with the high load head.

Check out our high temperature micro-scratch and impact testing tech note which describes case studies that combine the proven NanoTest high temperaturecapability with micro-scale scratch and impact tests on hard, wear-resistantcoatings.

| 标签: | 纳米压痕 纳米划痕 |