Interview CEO of H.E.L: Make a Healthier, more Sustainable, and Safer world

How to carry out process safety control? How to scale up the production scale from a 500 ml laboratory benchtop to a 10000 m3 factory? How to optimize the process to achieve sustainable development? How to improve production efficiency while reducing carbon emissions? In order to support a healthier, more sustainable, and safer world, H.E.L Group (H.E.L), founded 36 years ago, has spearheaded process optimization and reaction hazard assessment. H.E.L is a leading supplier of instruments and software for laboratories and testing facilities worldwide. Providing proprietary automation solutions for the global battery, pharmaceutical, biotechnology, chemical, and petrochemical industries. Since entering the Chinese market in 2009, H.E.L has provided efficient solutions for China's leading battery industry. After establishing its own subsidiary in 2020, its business in China has achieved rapid growth.

Recently, Antpedia interviewed Ms. Louise Madden, CEO of H.E.L, she shared the company’s development in global and Chinese localization. As well as H.E.L's leading position in hot areas, such as new energy batteries and life sciences, and looked forward to future industry trends and H.E.L's strategy.

Louise Madden

“My early education followed a very scientific pathway, studying Maths, Chemistry and Physics at A-Level. I went on to study Law & Accountancy at University and it wasn’t until some 11 years after graduating and having worked at KPMG, that I started to work in the scientific industry.” Louise said.

“Leaving KPMG, I took up the role of Finance Director at Farfield Group, a small scientific instrument manufacturer in Manchester, UK. Working in an SME gives you the opportunity to work outside your field of expertise and gain knowledge and hands on experience of other functions within a business. This led me to move to Sweden to take on the role of Global Service & Support Manager at Biolin Scientific, before returning to the UK to join Applied Photophysics where I was Chief Executive Officer, having also held positions as Chief Operating Officer and Commercial Director. In my current role as CEO at H.E.L Group (H.E.L) I have responsibility for operations in UK, Europe, North America, China, Singapore and India.”

Make a Healthier, more Sustainable, and Safer world

Louise provided the story of H.E.L's development history. Founded by Dr. Jasbir Singh, a chemical engineer, in 1987, 36 years ago, the company mainly engaged in process control and scaling up consulting work for clients. H.E.L was able to help their customers introduce new methods in the laboratory to ensure the safety of their chemical processes. As a consulting company, Jasbir realized the need for new scientific instruments to assist in the consultation and subsequently began manufacturing equipment. Not long after, customers began to ask, “Can I buy your equipment?” Therefore, in the early 1990s, H.E.L transformed from a consulting company to a scientific instrument manufacturer.

All of H.E.L ‘s businesses are built on safer processes, helping customers expand from laboratory workstations to manufacturing factories. Louise said, “H.E.L’s mission is to create a healthier, more sustainable, and safer world. Each of our products touches our customers’ processes in a different way, with a focus on process optimization, safety assurance, and scaling up. In the early days, H.E.L was very focused on chemical applications, but in the past decade or so, we have shifted our knowledge to biological and battery testing applications.

H.E.L established an agent office in China in 2009, and, based on the success of the partnership, established our own subsidiary in 2020. Led by Steven Chen, H.E.L transitioned to a wholly foreign-owned entity (WFOE) in China in 2020 to further expand sales, marketing and support efforts in H.E.L China’s core markets of battery testing and process safety.”

“We saw huge potential in the China market and felt that we would be better able to support our customers through a direct sales model – which has proven to be the case. We’ve also seen our revenue near-double over that time. In particular, we’ve seen high demand in our core Process Safety market and significant growth in battery testing applications, driven by investment in Electric Vehicle technology in China. The Chinese government has guided the transformation of the automotive industry towards electric vehicles, BYD is a world leader in battery technology, so in China, H.E.L's battery testing and application have achieved great success. China's biotechnology applications still have enormous growth potential. The fact has proven to be true, and after direct sales, H.E.L China's business has almost doubled.” said Louise,

“Today, HEL trading (Beijing) Co., Ltd. is led by Allen Wang, who was appointed General Manager of H.E.L China in January 2023 to drive the next stage of regional development including our expansion into new application areas and ongoing commercial effectiveness of the business.”

Four major product lines provide powerful application solutions

Louis next introduced H.E.L’s four major product lines and their powerful solutions for applications such as battery testing, process control and scaling up, chemical synthesis, and biotechnology.

Battery testing technology ensures safe battery development

Batteries power the world and with the need for higher energy densities, quicker charging times and longer lifetimes, safety and performance are crucial considerations in battery development. H.E.L’s battery testing product lines allow battery developers, manufacturers and integrators to test safe working limits of batteries and characterize battery performance under a range of conditions. Our product range is fully compliant with world-leading regulations in China for battery testing, such as the GB/T 36276-2018 regulations in China for battery testing. In H.E.L China, with >90% of sales revenue currently coming from this region.

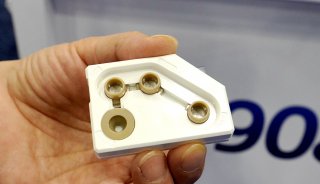

The BTC and iso-BTC product lines allow battery developers, manufacturers, and integrators to test safe working limits of batteries and complete systems and characterize battery performance under a range of conditions.

Left to right: BTC-130, BTC-500 Adiabatic Calorimeter, iso-BTC+ Floor Standing Isothermal Calorimeter for Battery Performance Testing

Batteries ultimately fail due to overheating. The BTC-130 and BTC-500 allow users to investigate the root cause, based on: operating temperature, physical damage, over-charging & discharging, and combinations of the above.

Once safe operating conditions have been established, the iso-BTC systems define optimum use conditions and improve overall battery pack design.

Users who apply H.E.L's safety battery development solution

Process safety and scale-up

In industries ranging from pharmaceuticals to fine chemicals, there is a need to take small, laboratory scale reactions to mass manufacture of a product. H.E.L’s process safety product lines allow customers to work at a safe bench-scale to evaluate and mitigate the risks of production scale chemical processes. This is an essential part of safe manufacturing process design, which saves lives and significant cost & reputational damage.

Based around thermal screening, adiabatic calorimetry, and reaction calorimetry, products such as the Phi-TEC I and Phi-TEC II enable users to work at a safe bench-scale to evaluate and mitigate the risks of production-scale chemical processes. H.E.L’s Simular reaction calorimeter also allows customers to understand the thermal properties of reactions and design them to be safer and more efficient. Uniquely, the configuration of the Dual-Simular allows users to work at atmospheric and raised pressures on one device.

From left to right: Phi-TEC I, Phi-TEC II calorimeters, Simular process development reaction calorimeters

Based on thermal screening (calorimetry) techniques, the H.E.L products are used to :

• Screen raw materials for thermal stability, over-pressure risks and define safe storage conditions

• Identify risks with heat-generating (exothermic) reactions which can lead to plant-scale disasters.

• Define fall-back safety approaches for plant-scale manufacture, such as vent sizing

• Design safe and efficient reaction conditions and identify cooling requirements

Users applying H.E.L’s Process Safety and Scale Up solutions

Chemical Synthesis: High temperature and high pressure automation system

From identifying active molecules through to pilot scale synthesis, H.E.L provides a comprehensive range of automated systems to facilitate chemical research, development, optimization, and scale-up. H.E.L’s products cover a wide range of applications that rely on automation to run high-pressure and high-temperature chemical reactions. The Chemical Synthesis portfolio is under-pinned by the PolyBLOCK platform and the power of our automation software WinISO and labCONSOL.

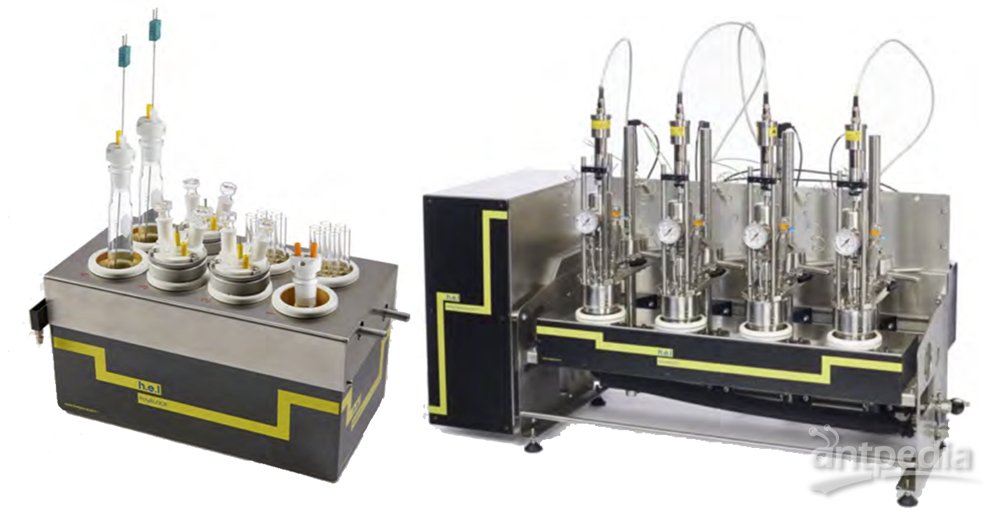

Most well-known is our PolyBLOCK parallel reactor system, which has up to eight reactors and can run any combination of experimental protocols simultaneously, completely automated. Typically, the PolyBLOCK is chosen by experts who have demanding applications to run.

Left to right: PolyBLOCK, AutoMATE chemical synthesis platform

H.E.L also have a wide range of systems for catalysis studies in this portfolio, from simple CAT batch autoclave reactors, through to the ChemSCAN system for parallel uptake studies and reaction optimization and the FlowCAT benchtop continuous flow catalysis system.

Left to right: CAT Catalyst Screening Platforms, ChemSCAN | Parallel Catalyst Screening and Development Platform, FlowCAT | A Bench-Top, High Pressure Flow Catalysis Platform

Typically used in research-scale labs, these products are used in a wide range of applications, including: Reaction design and optimization, Catalyst evaluation and hydrogenation efficiency analysis, Reaction scale-up and Accelerated life-time testing.

Users applying H.E.L's chemical synthesis solutions

Bioprocess development: Fastest growing market

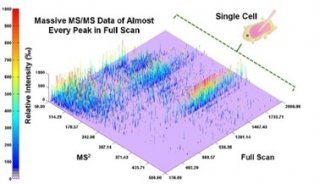

Based on the PolyBLOCK core technology and powered by the WinISO software platform, these systems enable complex, multiparameter biological experiments to run in parallel in a ‘set and forget’ manner. This is a high-demand, growing part of the H.E.L portfolio.

One of the fastest growing markets for H.E.L is our BioXplorer range of benchtop parallel bioreactors. With up to 16 user-defined reactor configurations, scientists can run a number of experiments simultaneously. What interests many of our customers is the ability to conduct bioculture experiments at bench-scale, utilizing elevated pressure, a feature not commonly available with other systems.

Left to right: BioXplorer 400, BioXplorer 5000 bioreactors

H.E.L’s BioXplorer platforms offer a unique solution that enables researchers to work with high-pressure fermentation conditions at bench-scale. The multi-liter versions support the initial transition into scale-up and process development for industrial biotechnology applications. Heavily installed in research settings, which have demand for a wide range of applications, including: technology to extract C1 gases, such as CO2 & CH3 out of the atmosphere, bioplastic and biofuel production, gut microbiome studies, ‘artificial meat’ food & feedstock development, bioprocess optimization (strain development and enzyme/protein production.)

Users who apply H.E.L's bioprocess development solutions

The mission of responding to the needs of the times

In recent years, human beings have paid greater attention to the environment, health, and sustainable development. Green chemistry, low-carbon technology, and life sciences have high popularity and development potential in scientific research, industrial applications, and policy levels. Louise also shared H.E.L's technical solutions in the aforementioned hot areas.

Green Chemistry: A critical part of green chemistry is to make processes as efficient, safe and reliable as possible. Our systems are deliberately designed to support customers in designing and optimizing reactions at bench scale before moving on to scale-up, pilot, or product scale batches. Every product decision we make is guided by our company mission to make the world healthier, safer and more sustainable for everyone.

Low-carbon: One of the reasons we are so keen on supporting the development of safe, effective batteries is that we see battery-based energy storage systems as critical in combatting climate change through greenhouse gas emissions. Clean electricity generation processes, such as solar or wind can’t be relied on for 24/7 production, but batteries can store the energy produced and even out the supply. There are environmental costs to developing, manufacturing, using, and disposing of batteries. We must therefore focus on safety and performance to get the most out of the batteries we consume, driving the highest environmental ROI.

At the other end of the equation, our pressurized bioreactor systems are being used to develop technology to suck C1 gases (such as CO2) out of the atmosphere to generate useful products such as bioplastics and biofuels, which are either carbon neutral or carbon negative.

Life Science: At H.E.L, we’re heavily invested in biotechnology applications. Following the COVID-19 pandemic, biopharma remains a strong market globally, and some of the new technologies and challenges unearthed by the pandemic are highlighting new opportunities in that space – for example -mRNA vaccines. We’re also exploring the non-pharma markets, such as industrial biotechnology applications. These include biofuels and bioplastic production, often using C1 capture technologies. We see biotechnology applications playing a significant role in our future product roadmap.

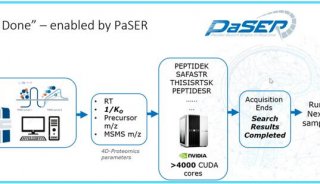

When it comes to the challenges in the field of process control, Louise said, “Key challenges we are currently facing in the industry surround the increased levels of automation of chemical and biological processes and the subsequent scale-up of these reactions. The switch from manual intervention to fully automated processes often require complete retraining and deskilling of staff and can have ethical implications, such as role redundancies. Additional security and privacy measures must be put in place to manage the digitalization of generated data and ensure ongoing responsible use of results. ”

Despite its challenges, automated process control is a critical aspect of the manufacturing and biopharma industries, and we anticipate seeing continued digitalization to further reduce costs and improve productivity, but also an increased focus on sustainability. By incorporating sustainability assessment tools into management systems, we can simultaneously evaluate and optimize process conditions and operations, minimizing waste and emissions to reduce environmental impact.

China’s market: Government initiatives, regulation compliance and broad cooperation

When it comes to the characteristics of the Chinese market, Louise said, “the market is driven by government initiatives, which means we see a more focused market in China in comparison to our other regions – this has been good for us in terms of the battery technology testing market over the past few years and our diverse portfolio means we can adapt to those changing market priorities.

Louise stated that driven by investment in new energy vehicle technology in China, H.E.L has seen high demand in the core process safety market and significant growth in battery testing applications. On the other hand, H.E.L needs to ensure that its equipment complies with China's leading battery testing regulations. Therefore, H.E.L has optimized the product to fully comply with the Chinese battery testing regulations "GB/T 36276-2018 Lithium ion Batteries for Electric Energy Storage".

“One of the main reasons we went to a direct sales model in China was to better support our customers, so we have invested heavily in our service team and their training (both directly in China and with support from the global team). We are delighted that Dr. Yifan (William) Yao is joining the H.E.L China team to provide applications support to our customers. We have also been setting up agreements with labs to further support our customers through evaluation experiments.” Louise said.

In May 2023, H.E.L entered a collaboration with the Reaction Risk Evaluation Laboratory (RHEL) of Gulei Institute of Petrochemical Research, Xiamen University, to establish a joint laboratory for calorimetric technology and thermal risk assessment of lithium-ion batteries. H.E.L’s adiabatic accelerated calorimeters, BTC-130 and BTC-500, will be used to simulate thermal runaway conditions and characterize thermal behavior.

New facility to expand production capacity, Working hard on new products development

“We are very excited about our upcoming move of our global headquarters to a new facility in Hemel Hempstead, UK, which will allow us greater throughput and better logistics capabilities, as well as a great working environment for our team. This move will have a positive impact on our team and our customers across the world.” Speaking of recent planning, Louise was very excited to say.

“We’re also working hard on new product development, with a focus on our software and informatics offering. Most recently, we launched labCONSOL V1.4, enabling our Phi-TEC systems to be run on labCONSOL, and offering an optimized user experience, a fully configurable workspace, and improved data-logging and graphing functionality. Across many applications, the power of software tools is proving transformational in research.”