桌面型电子束蒸发系统Modular Thin Film Deposition Systems for RF & DC Sputtering – EBeam Evaporation – Thermal Evaporation – Organic Evaporation – Research & Development – Teaching – Lift-Off – Metallisation

FTI are working in partnership with Korvus Technology to promote and market the HEX benchtop thin film deposition system. The HEX platform offers an un-matched level of user control and customization, designed to incorporate the latest thin film technologies and performance into a bench top platform. It can be operated both manually and automatically with a huge range of sources and system options. Its modularity and ease of use make it the ideal tool for clean rooms and training programs.

The HEX has been developed with student training in mind. Its modular construction allows various key elements to be exposed, discussed and interacted with, enabling student laboratories to fully explore the mechanical, material and growth elements of thin film research and nanomaterials.

The HEX’s ability to be quickly reconfigured at low additional expense allows it to provide easy training on a reproducible and recognizable platform for various deposition/coating techniques ranging from sample preparation for surface analysis to e-beam, sputtering, thermal, organics (for OLED research) and a range of other thin film deposition techniques.

Some of the typical applications for the HEX thin film deposition system are listed below, however the modular design of the system allow it to be reconfigured in minutes and ensure that it can be used for many more applications.

FTI 正与 Korvus 技术合作,推广并推广 HEX 桌面式薄膜沉积系统。HEX 平台提供不匹配的用户控制和自定义级别,旨在将最新的薄膜技术和性能集成到工作台平台中。它可以手动和自动操作与广泛的来源和系统选项。其模块化和易用性使其成为洁净室和培训计划的理想工具。

HEX 是在学生培训时开发的。其模块化结构允许各种关键元素被暴露、讨论和交互,使学生实验室能够充分探索薄膜研究和纳米材料的机械、材料和生长元素。

HEX 能够以较低的额外费用快速重新配置,从而在可重现和可识别的平台上轻松培训各种沉积/涂层技术,从表面分析的样品制备到电子束,溅射、热、有机物(用于OLED研究)和一系列其他薄膜沉积技术。

下面列出了 HEX 薄膜沉积系统的一些典型应用,但系统的模块化设计允许在几分钟内重新配置,并确保它可以用于更多应用。

Thermal Evaporation Sources 热蒸发源

Thermal Evaporation Sources 热蒸发源

用于从电阻加热的舟上简单蒸发材料。

HEX TES 包括单个热舟源,允许集成一系列热舟和灯丝。源操作简单,成本低,提供高效蒸发。

For simple evaporation of materials from resistively-heated boats.

The HEX TES includes a single thermal boat source, allowing integration of a range of thermal boats and filaments. The source is simple in operation and provides efficient evaporation at low cost.

Thermal Evaporation Source Data

| Boat/Filament Length舟/灯丝长度: | 1 7/8″ (Standard) |

| Max Current 电流: | 100A |

| Boat Material舟材质: | Ta, Mo, W |

Fission – Magnetron Sputtering Sources

Fission – Magnetron Sputtering Sources

For magnetron sputter deposition of metallic materials

The HEX system is designed to be an effective sputtering system for deposition of a wide range of thin films.

We offer sputtering sources with 1″ and 2″ diameter targets. The sputter sources are equipped with SmCo magnets and accept targets with thickness ranging from 1 to 6mm. The typical target usage is around 43% for non-magnetic materials.

The HEX Fission includes a shutter assembly and gas injection lines mounted onto the source mounting plate for clamping onto the side panel.

The N-Type connectors allow the HEX Fission to be configured for DC sputtering. The system geometry may accommodate up to three sputtering sources, which provides the opportunity to carry out co-sputtering of various materials and deposit multi-layered coatings.

Fission Data

| Target Diameter: | 2″ (50mm) |

| Max Target Thickness: | 6mm |

| Cooling: | Water (0.5l/min) |

| Gas Feed: | Integral, through gas hood |

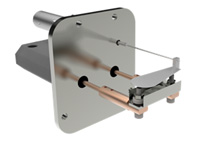

TAU – Mini E-beam Evaporator

For the evaporation of refractory materials or highly-controlled sub-monolayer films

The HEX TAU mini electron beam evaporators are employed to give maximum control of the evaporation rate at low fluxes and, importantly, to minimise contamination of the vapour stream for sensitive application areas such as surface science or thin-film doping. The construction of e-beam evaporators should therefore be aimed at maximising the evaporation control and minimising contamination. Both 1 and 4 pocket versions are available enabling co evaporation.

Electron beam evaporation is employed to provide a vapour stream from materials commonly difficult to evaporate with standard thermal techniques. An energetic electron beam is targeted onto the source material which has the effect of increasing the temperature. There is no intrinsic limit to the temperature which can be attained using this method, in contrast to conventional radiative or indirect resistive heating processes.

ORCA – Organic Evaporators

ORCA – Organic Evaporators

For the evaporation of organic materials

The HEX ORCA source enables the evaporation of organic materials. The source uses active crucible cooling to allow excellent temperature control even at low temperatures (200-300° C). Embedding of the thermocouple within the crucible allows extremely accurate temperature monitoring.

Quartz Crystal Monitors

Quartz Crystal Monitors

Thickness & rate monitoring

The HEX QCM enables the monitoring of deposition rate and thickness for all of the sources in the components range and is available in both manual and fully automated versions.

Sample Stages

Sample Stages

Basic, rotating, heated and cooled stages

The HEX can be configured with four sample stages. All the tables feature a convenient stand on the top of the system enabling simple sample exchange and preparation.

Basic – The basic, static sample stage can accept sample holders for 4 inch, 2 inch or multiple smaller samples.

Rotating – The rotating sample stage features a convenient, removable rotation actuator which will allow rotation from 2-20rpm.

Rotating/Heating – The rotating heating stage gives allows rotation from 2-20rpm and heating to 300°C.

Cooling – The cooled stage offers direct water-cooling cooling of the sample mounting stage, preventing overheating of sensitive materials during deposition.

|

除厂家/中国总经销商外,我们找不到

Korvus Hex300桌面型电子束蒸发系统 的一般经销商信息,有可能该产品在中国没有其它经销商。

如果您是,请告诉我们,我们的邮件地址是:sales@antpedia.net 请说明: 1.产品名称 2.公司介绍 3.联系方式 |

售后服务

我会维修/培训/做方法

如果您是一名工程师或者专业维修科学 仪器的服务商,都可参与登记,我们的平台 会为您的服务精确的定位并展示。