四球试验机中的KRL剪切稳定性测试

四球试验机中的KRL剪切稳定性测试

Lubricant formulations which ensure a stable viscosity under high shear rates (~107sec-1) are critical to ensure adequate film thickness to protect equipment from unacceptable wear and scuffing. Viscosity modifier used as additives are susceptible to degradation during mechanical shearing. The KRL shear stability test (CEC L-45-99) is considered one of the most severe tests to estimate the permanent change in viscosity caused by mechanical stresses and correlates well with the field data for a 60 hour test.

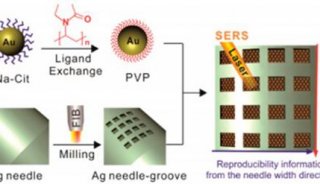

KRL shear stability module (KRL-SST) has been newly designed as an add-on attachment to the Ducom benchtop Four Ball Tester (FBT-3) thereby expanding its capabilities beyond wear preventive and extreme pressure performance evaluation. This new design has zero impact on the compactness and ease of operation of the existing FBT-3 system.

The module complies with the

CEC L-45-99 and DIN 51350-6 standards.

A tapered roller bearing (SKF32008XQ) for shearing the fluid replaces the standard four ball configuration. A special lubricant cup with fast response temperature sensor and integrated cooling channels is connected with a proprietary closed loop temperature control unit to maintain the temperature of 60 ± 1 °C.

This system uses ethylene glycol as a coolant for high precision temperature control for long duration tests lasting for hundred hours. The load and speed controls is enabled by automated loading and direct drive technology on FBT-3 .

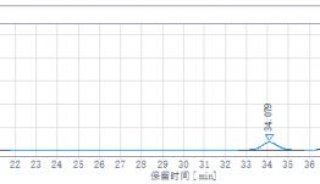

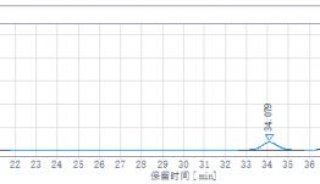

The performance of the KRL module has been extensively tested and validated using RL 209 oil (CEC L-45-99 reference oil for bearing qualification).

Table 1 describes the test conditions as per CEC L-45-99.

Parameters | Values |

Load (N) | 5000 ± 200 |

Speed (rpm) | 1475 ± 25 |

Oil temperature (°C) | 60 ± 1 |

Oil quantity (ml) | 40 |

Total number of revolutions | 1740000 ± 500 |

Duration (h / min) | 19 h 40 min ± 20 min |

-

招标采购

-

焦点事件

-

标准

-

焦点事件

-

产品技术

-

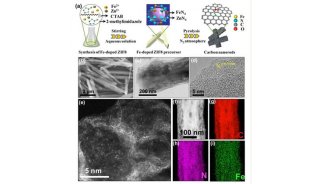

科技前沿

-

科技前沿

-

科技前沿

-

科技前沿

-

科技前沿

-

科技前沿

-

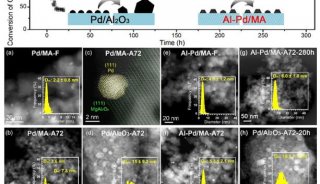

技术原理

-

项目成果

-

项目成果

-

项目成果

-

焦点事件

-

项目成果

-

标准

-

项目成果

-

项目成果

-

项目成果

-

项目成果

-

项目成果

-

科技前沿